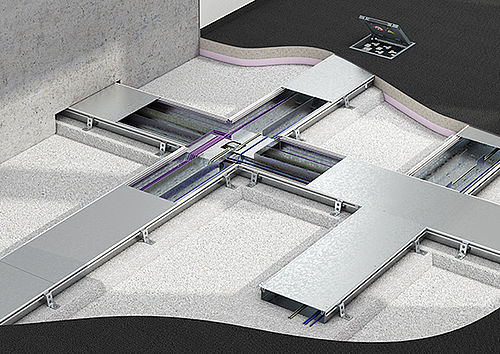

The open screed-flush trunking system OKA-T

The open, screed-flush trunking system OKA-T is used for the three-compartment cable routing and the installation of electrical resources in the underfloor area.

The OKA-T trunking system is suitable for the installation of the GES service units. According to the room use, service units for up to twelve Modul 45 single devices can be chosen. This corresponds to the installation of up to nine standard installation devices. The trunking covers can be opened along the entire length – even when installed with a floor covering.

This ensures that the underfloor installation trunkings stay accessible at any time. The underfloor trunking installation is thus particularly suitable for areas in which there are regular modifications to the routed cables ‒ such as offices, in which the workstations are not always in the same place.

Strong materials for the screed floor trunking system: The floor trough and trunking cover are made from galvanized sheet steel with a zinc coating of 275 g / m2 according to EN 10327 DX51D++ Z275-N-A-C.

Underfloor trunking system with set height: The OKA-T trunking system has a set height of 65 mm.

Scope of delivery of the underfloor trunking installation OKA-T: The mounting accessories required are included. The trunking units are supplied, ready-to-mount, with three covers.

For which floor care type is the OKA-T underfloor trunking system suitable?

The GES floor boxes, that can be installed inside the OKA-T trunking system, are suitable for dry cleaned floors.

The advantages of the screed-covered duct system OKA-T at a glance

- Maximum flexibility: The electrical installations inside the underfloor installation trunkings can be adjusted at any time.

- The trunkings are available in different widths and heights and there is also a large selection for device installation.

- The trunking system with closed floor trough offers a high level of security: Neither dust nor dirt can penetrate inside.

This underfloor trunking system is suitable for every installation situation

The side profiles contain an endless screw track for the fastening screws of the trunking covers, meaning that all the trunking covers can be mounted at any point in the trunking run.

High load capacity of the screed-floor trunking system

The side profiles support the screed connection of the trunking system, providing a high load capacity.

Creating equipotential bonding

Screwing the trunking covers to the side profiles means that all the metallic parts of the system have a conductive connection.

The trunking system can be included in the equipotential bonding safely and easily.

Which alternatives and variants of the underfloor trunking system are offered by OBO?

The EÜK-SN screed-covered duct system is the ideal electrical installation system for large areas with fixed furnishing plans, for example in office or administration buildings.

Duct sections and underfloor boxes form a tight grid, hidden in the screed, for cable routing. When combined with device installation units, access is given to power, data and multimedia technology.

Planning checklist for the screed-covered duct system OKA-T

When planning a screed-flush underfloor system, the following points should be observed.

- Matching of the floor structure with the architecture (screed bed, insulation layers, sealing etc.)

- Observe the minimum installation depth of device installation units.

- Matching the structural physics requirements (loads, impact sounds etc.)

- Select device installation units according to the floor cleaning method (wet care, dry care)

- When selecting the nominal trunking sizes take sufficient assignment reserves into account.